About Us

Vishakarma Tool Works is a famous name in the manufacturing, export and supply of premier range of tools and dies. Recognised in 1998, the company has grown and continuously adding values to its already existing setup. All our products are manufactured and supplied by us are acknowledged for their modular construction, consistency and long life. It is the uniqueness and the quality of our products that has helped us in gaining customers base at several parts of the world.

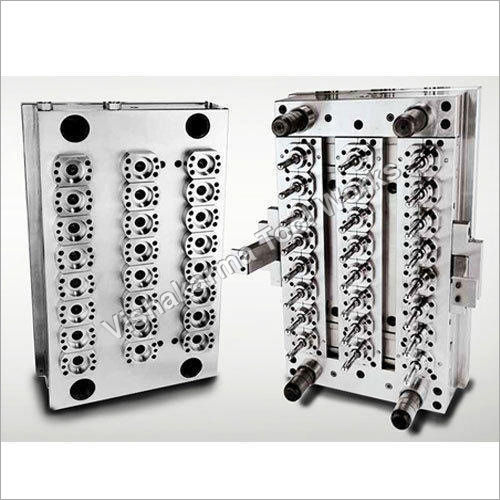

We manufacture different types of Tools and Dies, according to the requirement of international buyers. The tools and dies are made in different range of pet mould (From one cavity to 48 cavities) in different weight range of weight and heck (From 19 mm to 120 mm) from single to two stages. In a very short time span, we have expanded its business to be a global player in the tools and dies industry. The company aims to provide only the best products to sustain long lasting relationship with its customers.

Vishakarma Tool Works is a famous name in the manufacturing, export and supply of premier range of tools and dies. Recognised in 1998, the company has grown and continuously adding values to its already existing setup. All our products are manufactured and supplied by us are acknowledged for their modular construction, consistency and long life. It is the uniqueness and the quality of our products that has helped us in gaining customers base at several parts of the world.

We manufacture different types of Tools and Dies, according to the requirement of international buyers. The tools and dies are made in different range of pet mould (From one cavity to 48 cavities) in different weight range of weight and heck (From 19 mm to 120 mm) from single to two stages. In a very short time span, we have expanded its business to be a global player in the tools and dies industry. The company aims to provide only the best products to sustain long lasting relationship with its customers.

Make your

enquiry now !

Talk to us! we will be glad to assist

you.

Product Gallery

-

Precision Pet Preform Mould -

Fridge Bottles Mould -

Pet blow Preform moulds -

Pet Blow Preform Mould -

1 L Pet Bottle Mould -

5 Litre Bottle Mould -

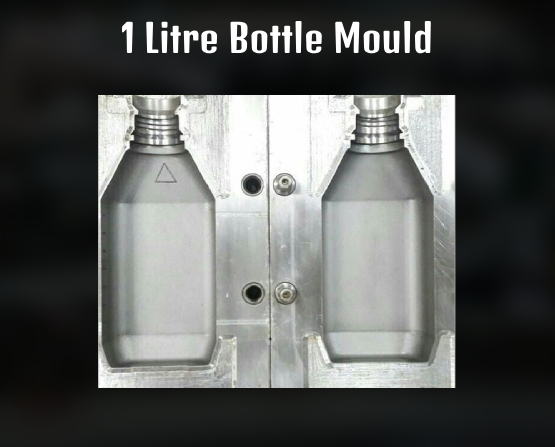

1 Litre Bottle Mould -

Pet Water Bottle Mould Die -

Industrial Pet Preform Mould -

Pet Preform Mould -

Pet Preform Mould -

Commercial Plastic Pet Blow Mould -

500 ml Pet Blow Mould -

Industrial Blow Mould -

Mould Base Die Tool -

Pet Bottle Mould -

Durable Pet Blow Mould -

4 Cavity Pet Blow Mould -

20 L Pet Water Blow Mould -

PET Preform Mould Spare Parts -

Stainless Steel Pet Die Mould -

PET Preform Mould For Jars -

Preform Mould For Pet Bottles -

PET Preform Mould -

Industrial PET Preform Mould -

Hot Runner Preform Mould

Infrastructure

Vishwakarma Tools is well equipped with advance testing tools. The company has commissioned a team of quality checking experts who does the final inspection according to the ISO standards. We have two production lines operational under full capacity and can provide the custom made Tools & Dies following the requirements of international buyers. The team at Vishakarma comprises of skilled employees who are proficient in manufacturing tools and dies.

Design and Engineering

We have understood that nowadays, product differentiation is the key to outstanding packaging. Thus, we provide a complete confidential latest design service with functionality to address any demand in assembling, modeling and production. Our latest tools designs have resulted in competitive tooling costs, processing-friendly products without compromising on quick delivery times. With the combination of our trained experience and clients input regarding specific requirement and challenges, the concepts are given shapes & design. This way we get an opportunity to work closely with customers.

Pro E Modeling and manufacturing bundle. Visi, Unigraphics and Solid Works are outsourced. "CNC Machine has the accuracy to machine tight and repetitive dimensions if they are programmed appropriately.

Mission

Our mission is to deliver an unparalleled level of service, while considering your complete satisfaction and peace of mind. Our dedicated team is ready to provide you any specific advice you need, so that you can choose the right product as per your specific requirement.

CAD/CAM

Having understood that in today's world, product differentiation is the key to outstanding packaging, we offer a complete confidential innovative design service with functionality to address any demand in modelling, assembling, production. Our innovative tools designs have resulted in very competitive tooling costs, processing-friendly products without any compromise on quality and quick lead times.

Concepts are given shapes with our experience and customer inputesregarding specific requirements and challenges. This gives us an opportunity working closely with clients.

Pro E Modelling and manufacturing bundle. Visi, Unigraphics and Solid Works are outsourced.

CNC Machine have the accuracy to machine tight and repetitive dimensions if they are programmed appropriately.

This dynamic company is constantly investing in the latest machining technologies. In order to ensure high quality and meet delivery commitments, the company is marching toward ISO 9001:2000 with an emphasis on full proof process control and quick production cycle turned around. Inspection is carried out at the end of every machining activity during the process and comprehensive exhaustive inspection before delivery to ensure that toolings meet specifications.

Quality Assurance / Inspection

Quality is the sum and substance of all phases of our operation. We recognize quality as an equal partner to price and delivery, and have implemented the latest inspection equipment and methodology in both our quality control department as well as the machining environment.

Technical skills, customer interaction and advanced equipments fuse together to assure thet accuracy and quality are not left to chance. Processing Technicians for all types of processing in PET, we have highly trained operators with years of experience in production environment.

Vishwakarma Tools is well equipped with advance testing tools. The company has commissioned a team of quality checking experts who does the final inspection according to the ISO standards. We have two production lines operational under full capacity and can provide the custom made Tools & Dies following the requirements of international buyers. The team at Vishakarma comprises of skilled employees who are proficient in manufacturing tools and dies.

Design and Engineering

We have understood that nowadays, product differentiation is the key to outstanding packaging. Thus, we provide a complete confidential latest design service with functionality to address any demand in assembling, modeling and production. Our latest tools designs have resulted in competitive tooling costs, processing-friendly products without compromising on quick delivery times. With the combination of our trained experience and clients input regarding specific requirement and challenges, the concepts are given shapes & design. This way we get an opportunity to work closely with customers.

Pro E Modeling and manufacturing bundle. Visi, Unigraphics and Solid Works are outsourced. "CNC Machine has the accuracy to machine tight and repetitive dimensions if they are programmed appropriately.

- CNC Spark Erosion with D.R.O.

- Fully - automatic Cylindrical Grinders

- CNC Lathes

- Vertical Milling Machines with D.R.O.

- Lathes

- Spark Erosion

- Cutting Machine

- Shaper

- Surface Grinders

- Vertical Drillers

Mission

Our mission is to deliver an unparalleled level of service, while considering your complete satisfaction and peace of mind. Our dedicated team is ready to provide you any specific advice you need, so that you can choose the right product as per your specific requirement.

CAD/CAM

Having understood that in today's world, product differentiation is the key to outstanding packaging, we offer a complete confidential innovative design service with functionality to address any demand in modelling, assembling, production. Our innovative tools designs have resulted in very competitive tooling costs, processing-friendly products without any compromise on quality and quick lead times.

Concepts are given shapes with our experience and customer inputesregarding specific requirements and challenges. This gives us an opportunity working closely with clients.

Pro E Modelling and manufacturing bundle. Visi, Unigraphics and Solid Works are outsourced.

CNC Machine have the accuracy to machine tight and repetitive dimensions if they are programmed appropriately.

- CNC Milling (BMC)

- CNC Spark Erosion with D.R.O.

- Fully - automatic Cylindrical Grinders

- CNC Lathes

- Vertical Milling Machines with D.R.O.

- Lathes

- Spark Erosion

- Cutting Machine

- Shaper

- Surface Grinders

- Vertical Drillers

- Hi-Speed Polishing kits (pneumatic and electrically-operated types)

This dynamic company is constantly investing in the latest machining technologies. In order to ensure high quality and meet delivery commitments, the company is marching toward ISO 9001:2000 with an emphasis on full proof process control and quick production cycle turned around. Inspection is carried out at the end of every machining activity during the process and comprehensive exhaustive inspection before delivery to ensure that toolings meet specifications.

Quality Assurance / Inspection

Quality is the sum and substance of all phases of our operation. We recognize quality as an equal partner to price and delivery, and have implemented the latest inspection equipment and methodology in both our quality control department as well as the machining environment.

- Contracer, Mitutoyo

- Plotter

Technical skills, customer interaction and advanced equipments fuse together to assure thet accuracy and quality are not left to chance. Processing Technicians for all types of processing in PET, we have highly trained operators with years of experience in production environment.

|

VISHAKARMA TOOL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |